Control cabs and software

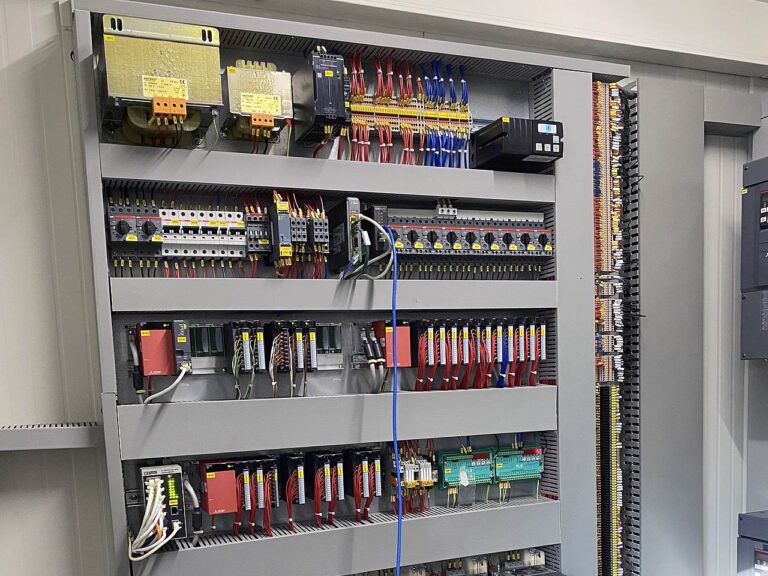

The control cabins produced by Bernardi Impianti represent the operational center of the entire plant. They contain all the electrical and electronic control equipment of the single machines that make up the plant.

Control cabins and asphalt plant software

The control cabins produced by Bernardi Impianti represent the operational center of the entire plant.

They contain all the electrical and electronic control equipment of the single machines that make up the plant.

This solution allows total protection of the equipment, greater safety and facilitates any maintenance interventions.

The control cabin is divided into two sections: one intended for housing the equipment, access to which is reserved for specialized technicians only and therefore, suitably protected to prevent the entry of unauthorized persons, the other intended to accommodate the personnel in charge to the running of the plant.

Control cabin features and software

All cabins are suitably air-conditioned to ensure optimal habitability and can be customized with particular interior arrangements and furnishings according to the customer’s needs. They have a large glazed surface, with anodized aluminum frames, to give the operator maximum visibility of the machine.

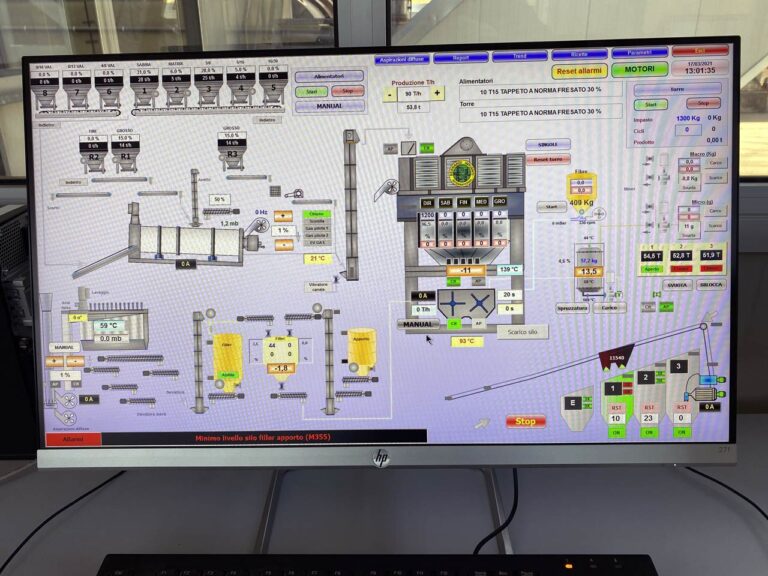

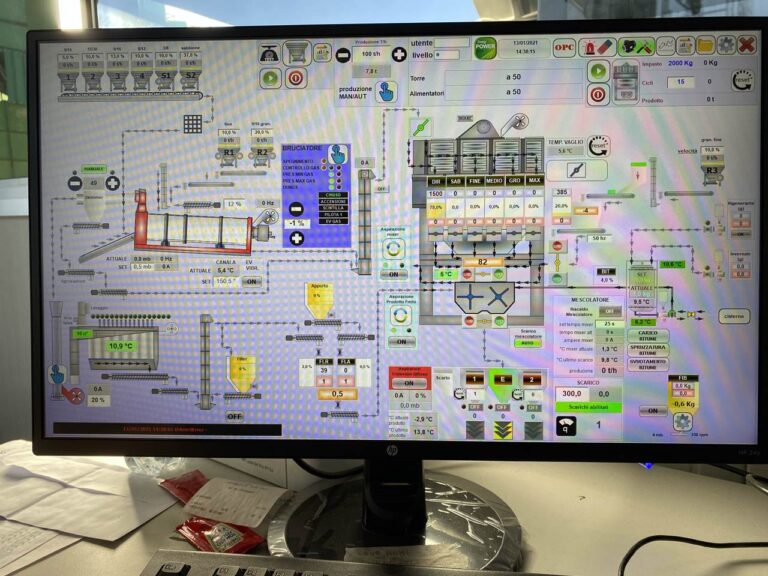

The control of all functions is based on a complex computer system designed by Bernardi Impianti, extremely flexible, easy to use and learn.

The control system is completely computerized with P.L.C. (located in the control room or power area), PC suitable for the use of latest generation software, LCD color video, keyboard, mouse.

The supervision SOFTWARE program for the operation of the machine consists of a series of graphic pages, shown in full screen, above which there is a series of icons that allow access to the management of recipes, if any, (if provided) , visualization of graphical trends, visualization and printing of reports, alarm page with historical visualization.

The system may also include:

- a module for remote assistance via internet that allows access to the PLC LAN network for software monitoring and / or modification via a secure remote connection (proprietary VPN);

- software dedicated to communication between the IT and OT areas and to allow machine-factory data exchange.